SPECIFICATIONS

Trojan Industries and our supply partners manufacture in accordance with both international and Canadian standards and specifications.

For specific products supplied by Trojan Industries, please contact us for more details on the specifications that are used to manufacture products.

Trojan Industries is also committed to helping our customers write specifications that are tailored to their individual and specific needs.

SPECIFICATIONS SAVE TIME, MATERIAL, AND LIVES

We take meeting your specifications seriously and that’s why we spend time, money, and expertise every day to develop proper design and engineering, on testing, and documentation of how we meet your specifications. Those investments provide our customers with peace of mind because our solutions will provide value, durability, and safety.

CONSTRUCTION CASTINGS AND AASHTO-M306-10

AASHTO M306-10 is the standard specification for drainage, sewer, utility, and related castings. It’s smart, it provides you with peace of mind, and us with the ability to continually innovate better ways to meet your performance based requirements. We recommend that every municipal authority adopt it as their specification for their standard castings subject to wheel loads. Here is a link to the AASHTO website where you may purchase a copy for review. Reach out to our team if you have any questions about the advantages of adopting this specification.

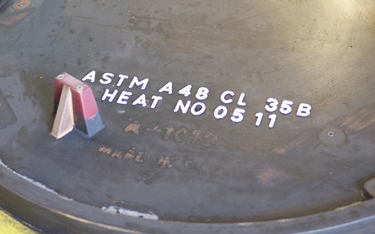

Material Quality

All metal used in D&L Castings shall conform to ASTM A-48 Class 35B for grey iron and to the ASTM A-536 Class 80-55-06 for ductile iron. Castings shall meet Federal Specification A-A60005 (formerly RR-F-621E).

Finish of Product

All rings and covers that are round will have machined surfaces that insure a no-rock and non-rattle fit. All components must fit satisfactorily and be true to the pattern from which they are made.

Tolerance

Dimensions may vary in the casting due to shrinkage, no more than +/- 1/16 inch per foot.

Green Sand Molding

Most D&L Foundry castings are cast using green sand molding. See below for more information.

Submittal Drawings

D&L Foundry will provide shop drawings upon request for submittal to engineers approval. The engineer will always have the right to reject any casting that does not conform to the specifications. If the D&L standard design has been altered and a new shop drawing has been submitted, the same rights will be in effect for the engineer.

Ductile Iron

Many D&L castings are available in ductile iron. Stronger than grey iron or structural carbon steel, ductile iron is more suitable for unusual situations such as extreme cold or heat and for stresses greater than H20 loadings. This includes airports, forklift traffic, extra-duty freeway traffic and containers ports. Also, using a grey iron frame in combination with a ductile iron lid is suitable for many sites.

Please call and consult with Trojan staff for recommendations when considering ductile iron in a specific application.

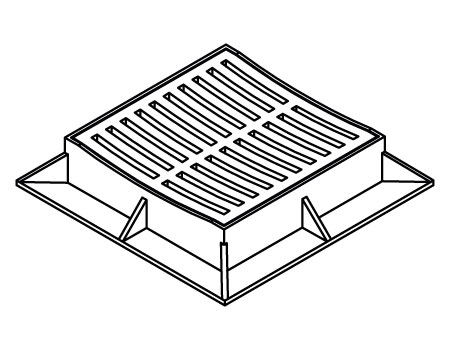

Green Sand Molding and Draft in Castings

The casting process utilizes the environmentally friendly Green Sand method. Sand is shaped into molds into which molten iron is poured. Each vertical portion of the casting will necessarily be angled slightly to enable the casting’s smooth release from the two halves of the sand mold. This “draft”, or slight angle, though always present in actual castings, is commonly not represented either visually or dimensionally in technical drawings for manhole covers, for simplification.

Hence, though the drawing in our catalog may show a vertical wall for a given casting, the actual thickness will not be uniform from top to bottom, but will flare slightly as described. This discrepancy is common for the iron castings and should not be used as a basis for casting rejection.

Load Capacities

In accordance with U.S. Government requirements, D&L Foundry and Supply conforms to Federal Specification A-A60005 in the testing of our products. As specified, a certain load is placed on a 9″ by 9″ area on a given casting, which is then inspected for cracks, defects or buckling.

Load Rating

Many of the castings featured in our catalog are capable of sustaining single axle trucks (H20-44 wheel loading) or tandem axle trucks (HS20-44 wheel loading), both of which support 32,000 lbs. per axle, or 16,000 lbs. per set of dual wheels.

Feel free to call our specialists with any questions regarding your load requirements for your project.

D&L products herein are assigned a load capacity rating of:

Heavy Duty Airport:

For those which sustain loads of 150,000 lbs. to 300,000 lbs.

Heavy Duty:

For those which sustain standard highway loads and H20 loads to 16,000 lbs. and above.

Light Duty:

For loads smaller than 2,000 lbs.